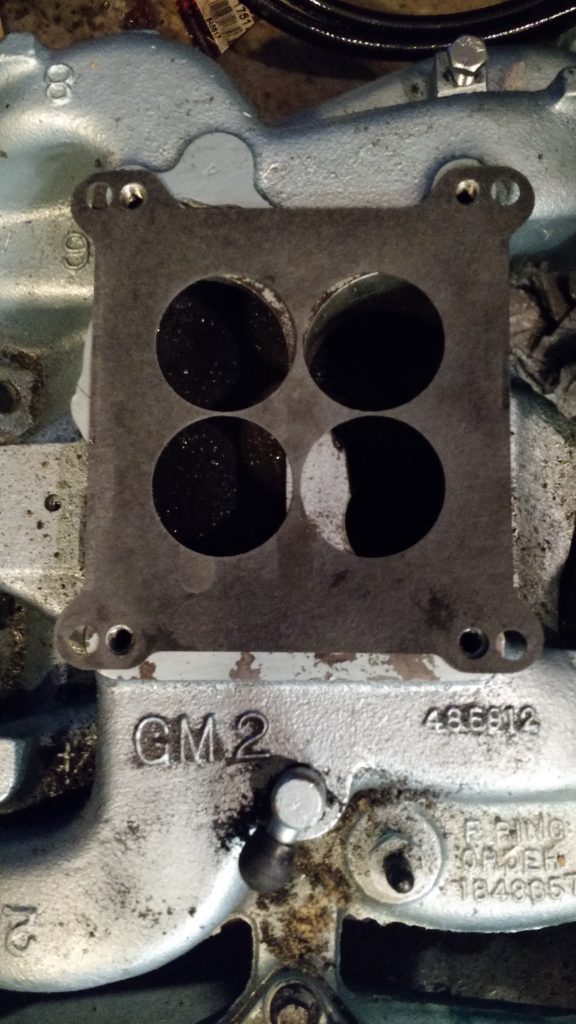

I finally got around to modifying my factory 1972 Pontiac Quadrajet spread-bore intake to accept the square-bore FiTech throttle body EFI. The results are in, the car runs smoother than ever and I can now mount my shaker to the throttle body using the factory air cleaner base!

Modifying a Pontiac Quadrajet intake to accept a square bore throttle body

Note that these instructions are for modifying a Pontiac intake designed for a Quadrajet spread-bore carburetor. Modifying a spread-bore intake for other manufacturers will more than likely be slightly different. Please note that your intake’s runners may be positioned differently thus requiring different attention where to modify.

Modifying a factory intake is not hard and only requires a few tools. Here’s the short list of tools necessary:

- Reciprocating saw (Sawzall) with bi-metal blades

- WD40 (or better cutting specific oil)

- Die grinder (powered by an air compressor recommended)

- Carbide Burr set (you may want to use both a cylindrical shape one as well as a small ball or tree shaped one to finish off corners)

First, do not modify the intake on your vehicle! First think you need to do is remove the intake manifold. For a pontiac, this requires draining (or partially draining) the coolant enough that removing the intake does not cause drainage from the water crossover in the front of the intake. The draw-down bolt will also require you to remove at least the alternator and in my case, power steering brackets in order to access. I spent more time taking the intake manifold off and bagging/tagging everything than I did actually modifying the intake.

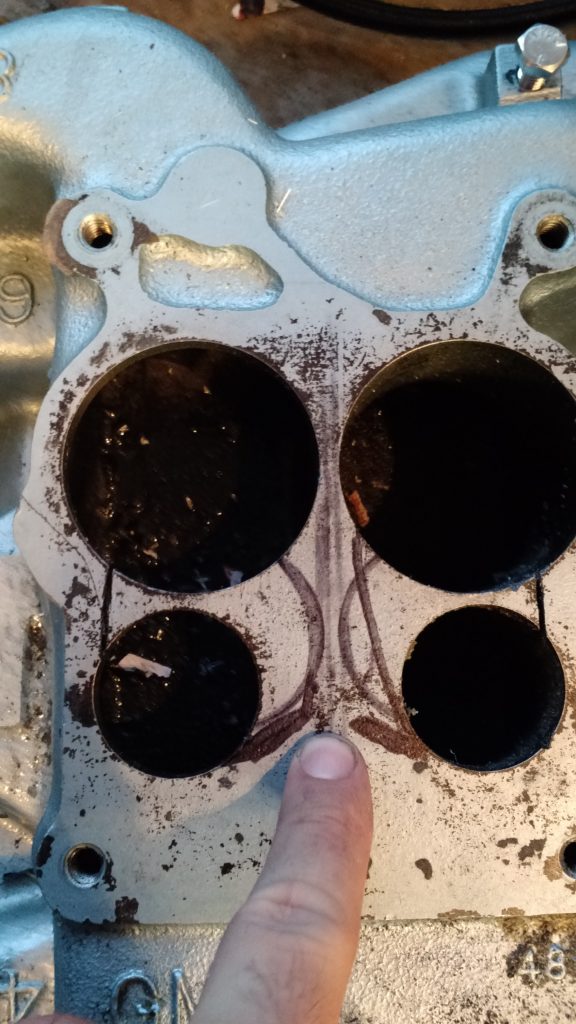

Modifying the intake spread bore openings

You want to make cuts with the saw to remove as much material as possible taking into consideration that some locations you do not want to remove too much material and expose the other side of the intake. Remember these intakes are dual plane and the last thing you want is to poke a hole in the wrong location!

Reinstall intake

Once I was done, I washed the intake 3 times then followed the normal directions for installing the intake. The only thing I do that is sometimes not mentioned in manuals is use RTV sealer round the draw down rubber washer (this is the rubber washer that a new intake manifold gasket set will come with that goes between the intake and the timing chain/water pump cover) as well as around the water crossover ports that run to the heads. I am not a big fan of over using RTV sealer, I essentially used enough that when you torque the bolts down you just see a sliver of RTV squeeze out of the mating parts. If you see gobs of RTV sealer oozing out between your parts, then I think you’re using too much.

When I set the intake in place, I just tightened the 10 bolts until they started to grab the intake. Then I torqued the draw down bolt to 15 ft/lbs. Following that I torqued the intake bolts from the center out to 15 ft/lbs, then 30 ft/lbs, then ending with 40 ft/lbs. Everything else I re-connected including the top radiator hose, fuel lines, and wiring for the FiTech.

Modified Intake Results: Shaker fits perfectly!

I can now use the factory air cleaner and shaker with the FiTech!

Remounting the Blaster SS Coil

During the process of pulling the intake manifold off the car and modifying it, I noticed that one of the 3 mounts for the Blaster SS Coil had ripped leaving the coil dangling in a not so desired way off of the firewall. Even tough MSD claims you can mount the Blaster SS Coil in any way you like, I determined that the rubber mounts that the Blaster SS comes with are not up to the task of holding the weight of the coil in any other direction but vertically.

At the last minute I created a new mount out of 3/16″ thick 2″ wide aluminum plate and fastened it to the choke side of the intake manifold. I am not sure I will leave it here since I think this creates too much heat in this location, but I will give it a try for a couple weeks at least.